Cambridge researchers have captured the visible nanostructure of wood in its live hydrated state for the first time using an advanced low-temperature scanning electron microscope.

Architects and engineers are increasingly considering wood as a lighter and more sustainable construction alternative to steel and concrete. While wood has been used in buildings for millennia, its mechanical properties have not, as yet, measured-up to all modern building standards for major superstructures. This is partly caused by our limited understanding of the basic structure of wood.

Plant and microscopy scientists at the Sainsbury Laboratory Cambridge University (SLCU) teamed up with researchers from Professor Paul Dupree’s group at Cambridge’s Department of Biochemistry to capture for the first time the visible nanostructure of ‘living’ wood using an advanced low-temperature scanning electron microscope (cryo-SEM).

The research, published today in the journal Frontiers in Plant Science, has also identified a non-tree plant Arabidopsis thaliana as a suitable model to use in further research into understanding how woody tissue develops.

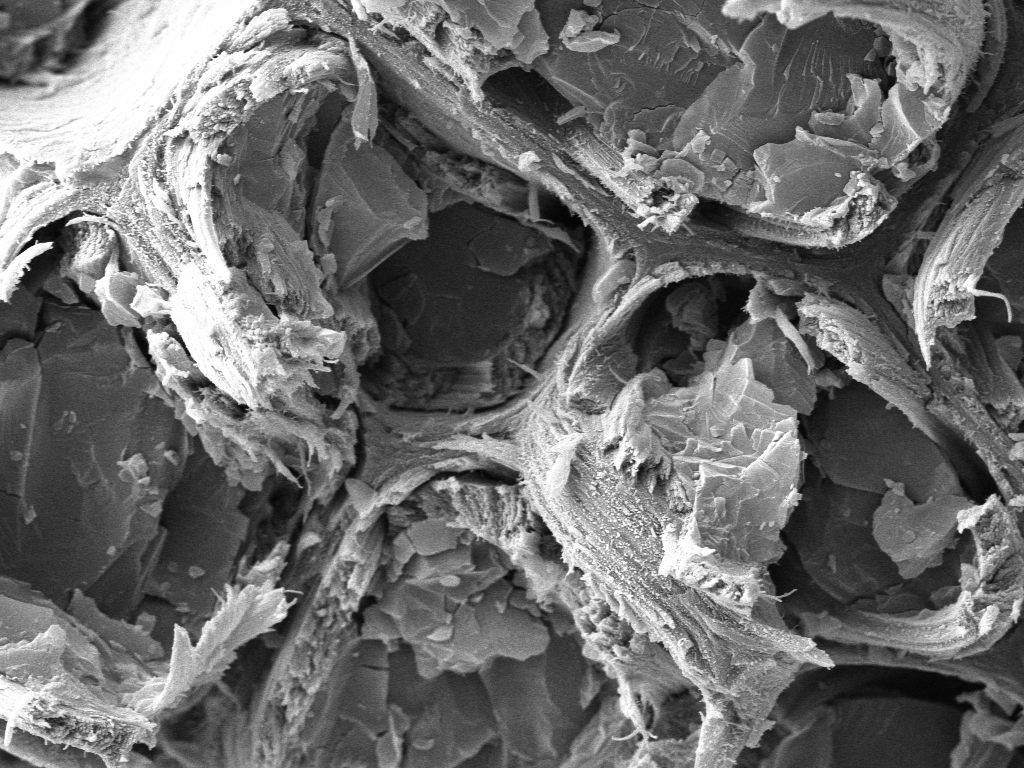

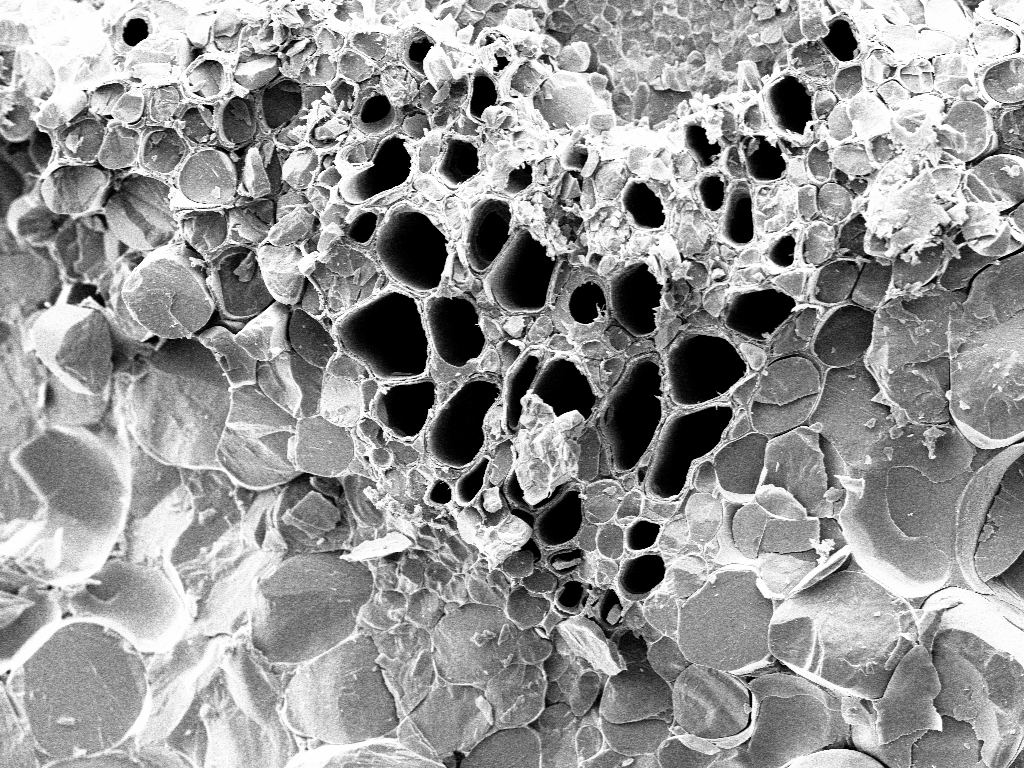

“The main building blocks of wood are the rigid secondary walls around each wood cell, which are made of a matrix of large polymers called cellulose and hemicellulose and are impregnated with lignin,” explains Dr Jan Lyczakowski, the paper’s first author from Cambridge University’s Department of Biochemistry, who is now based at Jagiellonian University. “It is the molecular architecture of wood that determines its strength, but we don’t yet know in detail the precise arrangement of these polymer molecules into cylindrical structures called macrofibrils, the composition of macrofibrils, if the arrangement differs between plants and how this might impact on wood density and strength.”

To compare different plants, the team collected wood samples from three trees – spruce, ginkgo and poplar – from the Cambridge University Botanic Garden. They snap-froze the freshly collected samples down to minus 200°C in liquid nitrogen slush under a high vacuum to preserve the cells in their live hydrated state and then coated the samples in an ultra-thin platinum film three nanometres thick to give good visible contrast under the microscope.

Dr Raymond Wightman, who is SLCU’s Microscopy Core Facility Manager, said the cryo-SEM is a powerful imaging tool to help understand various processes underlying plant development and has provided nanoscale detail of the secondary cell wall macrofibrils, which are 1000 times narrower than the width of a human hair. “Previous microscopy of wood was limited to dehydrated wood samples that had to be either dried, heated or chemically processed before they could be imaged. Our cryo-SEM is a significant advance over previously used techniques and has allowed us to image for the first time hydrated wood cells, showing macrofibril structures with a diameter exceeding 10 nanometres are present in both softwood and hardwood species and confirming that they are common across all trees studied.”

|

What is wood? Trees such as the giant sequoia (redwood) can only achieve their vast heights because of secondary cell walls that provide a rigid structure around the cells in their trunks. It is these secondary cell wall tissues that prevent crops lodging (falling over) and reinforce vascular tissues (xylem vessel walls) for efficient transport of water from the roots to the top of all plants. Woody secondary cell walls of plants are the largest carbon sink on the planet that not only captures carbon, but also offer a source of sustainable material and energy. |

In addition to imaging the three trees, the team also imaged the secondary cell walls of an annual plant, which is widely used as the standard reference plant for genetics and molecular biology research, Arabidopsis thaliana, and found that it too had prominent macrofibril structures.

Dr Matthieu Bourdon, a Research Associate in the Helariutta group at SLCU, said this discovery meant Arabidopsis could be used as a model for further research on wood architecture: “We have a collection of secondary cell wall related mutants in Arabidopsis, that show different phenotypes (traits),” Dr Bourdon said. “These mutants allowed us to determine the contribution of molecules like cellulose, xylan, lignin and galactoglucomannan to macrofibril formation and maturation. As a result, we are now developing a better understanding of what processes are involved in assembling cell walls. The wealth of Arabidopsis genetic resources offers a valuable tool to further study the complex deposition of secondary cell wall polymers and their role in defining the cell wall ultrastructure and how they mature into wood.”

Professor Dupree and Dr Lyczakowski are involved in the Leverhulme Trust funded Natural Material Innovation Centre where a team of biochemists, plant scientists, architects, mathematicians and chemists from the University of Cambridge is working towards better understanding of wood structure, modification and application. The researchers are hoping they can make wooden skyscrapers, and even wooden cars, a reality by re-engineering the structure of wood in order to make better materials for construction and manufacturing. Their work was recently showcased at the Royal Society Summer Science Exhibition in London.

Professor Dupree said understanding how the wood components (polysaccharides and lignin) come together to make these super strong macrofibril structures is important for understanding both plant maturation and new materials design.

“Visualising the molecular architecture of wood allows us to now investigate how changing the arrangement of cellulose, hemicellulose and lignin might alter its strength,” Professor Dupree said. “There is increasing interest around the world in using timber as a lighter and greener construction material. British Columbia in Canada recently doubled its allowable height for wood-framed buildings to 12 storeys and if we can increase the strength of timber we may start seeing more major constructions moving away from steel and concrete to timber. A better understanding of the composition and structure of woody plants will eventually enable us to grow more efficient biofuel feedstocks and develop other novel biomaterials with advanced properties.”

Dr Lyczakowski, who is currently based at the Jagiellonian University in Krakow, Poland, hopes to continue this work to explore further how changes in the structure of macrofibrils can be linked to strength and density of wood from coniferous trees. To do that he will be visiting SLCU next summer to conduct more research as part of his funding from the National Science Centre Poland. As conifers make industrially important softwood the hope is that this research may contribute to improvements in a range of processes from paper manufacturing to building construction.

Reference

Jan J. Lyczakowski, Matthieu Bourdon, Oliver M. Terrett, Ykä Helariutta, Raymond Wightman, Paul Dupree. (2019) Structural imaging of native cryo-preserved secondary cell walls reveals the presence of macrofibrils and their formation requires normal cellulose, lignin and xylan biosynthesis. Frontiers in Plant Science.

Funding

This work was supported by the Leverhulme Trust Centre for Natural Material Innovation, US Department of Energy, BBSRC, ERC and Gatsby Charitable Foundation.